2020-2024

In the upcoming four years, Umka cardboard mill, plans to invest around 40 million euros in modernisation and improvement of the existing production technology, as well as in a system for biological water treatment. The aim of this investment cycle is to further develop production capacity, while preserving the eco system in its environment.

Due to the complexity and scope of the investment, the investment as well as implementation works will be divided into two phases.

The first phase of the investment cycle in amount of 30 million euros includes following:

- Installation of a new fourdrinier forming section and reconstruction of the coating section which includes the installation of a Curtain coater

- Installation of a new winder and a system for biological water treatment,

- Rebuild of the press section, as well as the stock preparation lines.

The second phase of the investment cycle in amount of 10 million euros includes following investment activities:

- Rebuild of the steam-condensation system, and the ventilation in the drying section,

- Increasement in capacity of the coating kitchen

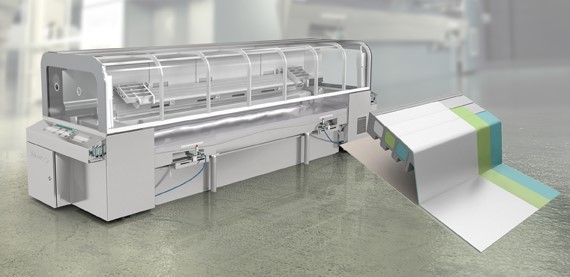

- Installation of a new reel packing line and upgrade of the automatic packing line

With the realization of the above-mentioned investments Umka will produce grammages in the range of 160-450 g /m2, while the speed of the machine will be increased up to 600 m/min. The daily production capacity is expected to be around 620 tons, or up to 220,000 tons annually, depending on the order structure.

The main partner and supplier is a Finnish company Valmet. Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. Currently, Valmet has approximately 13,000 employees worldwide, and with a history of more than 200 years, the company has significant references in its portfolio.